WEST COAST INSULATING GLASS – NOTHING BUT THE BEST

.

Charles “Rusty” Neubauer, President and Founder of West Coast Insulated Glass Products back in 1988, had recognised a market niche, to specifically service California, Nevada and Arizona with only the very best specification Insulated, Tempered and Laminated glass products.

Charles “Rusty” Neubauer, President and Founder of West Coast Insulated Glass Products back in 1988, had recognised a market niche, to specifically service California, Nevada and Arizona with only the very best specification Insulated, Tempered and Laminated glass products.

.

“Our glass customers provide doors and windows for clients that demand the finest possible products,” says Rusty. “Diamond” quality is what they want. The old adage “glass is to look through, not look at” does not fly with this crowd,…and we are the supplier they count on to provide that quality.”

.

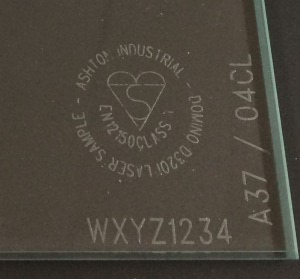

“After installing our second tempering furnace we found our seaming department was having trouble keeping up with demand. We previously installed an Ashton Laser logo machine to help speed up the logo process. Having over 50 customer defined logo positions and speed of marking, made the purchasing decision that much easier. Now we just scan a barcode label, and the proper logo and position is instantly ready for marking.

.

With the increased seaming demand and ever-larger lites being requested, some as large as 80 sq ft., we found our people were having a difficult time keeping pace with production expectations. Quality issues were happening particularly with soft coated products; The need to process quickly yet with less handling was necessary.”

With the increased seaming demand and ever-larger lites being requested, some as large as 80 sq ft., we found our people were having a difficult time keeping pace with production expectations. Quality issues were happening particularly with soft coated products; The need to process quickly yet with less handling was necessary.”

.

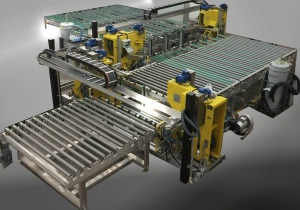

Rusty had been in discussions with Ashton Industrial about a seaming line since 2010 but was never really a fan of wet seaming or grinding systems. Dry systems had been developed, and when Rusty saw first-hand the latest SEAMMAXX-PRO™ in dry running design at Glasstec 2016 an order was made shortly thereafter for a fully automatic 4m x 2.5m [155” x 100”] line with laser marking.

.

“We are very happy with the SEAMMAXX-PRO™ line: speed and consistent quality of the edge seam, reduced handling and a big improvement in yield. We process 1/8” through 1/2″ in random sizes and thicknesses two shifts per day. We have noticed a major decrease in defects from manual seaming and our employees are handling the glass much less between cutting, seaming and tempering which reduces remakes. Breakage from the tempering process is way down. We currently run all glass destined to be tempered or laminated through the seaming line and have no production bottleneck issues at all. “

“We are very happy with the SEAMMAXX-PRO™ line: speed and consistent quality of the edge seam, reduced handling and a big improvement in yield. We process 1/8” through 1/2″ in random sizes and thicknesses two shifts per day. We have noticed a major decrease in defects from manual seaming and our employees are handling the glass much less between cutting, seaming and tempering which reduces remakes. Breakage from the tempering process is way down. We currently run all glass destined to be tempered or laminated through the seaming line and have no production bottleneck issues at all. “

![]() .

.

.

.

17730 Crusader Ave.Cerritos, CA. 90703

562-653-9797