ROBOLOAD-PRO™ AUTOMATIC LOADING & UNLOADING SYSTEMS

For high speed loading of lites in series mode (long runs of equal sizes) the ROBOLOAD-PRO is a robust high performance solution that can lift singles or pairs or multiples presented in racks and load these within a cycle time of under 15 seconds.

In standard, there are at least two rack loading positions, each mounted within its own safety enclosure. Guarding is organised in such a way that access to the robot working area is automatically physically blocked whenever a rack change is being performed.

All access points are fully interlocked and will cause the robot to E-Stop if breached. A controlled shutdown or isolation procedure is provided to provide safe access when required.

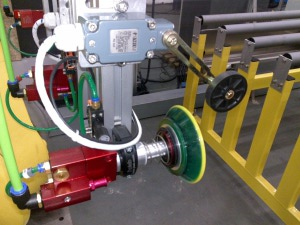

ROBOLOAD-PRO comes complete with its own roller conveyor, where lites can be loaded from above or optionally coated-side-up where the ROBOLOAD-PRO™ vacuum frame passes through the conveyor rollers. It includes controls to accept multiple lites loaded in a row and to ‘peel’ single lites from the row and feed them singly into a SEAMMAXX-PRO seaming line or other production process.

Offloading applications can be programmed for single or multiple lites, including pre-indexing and row building prior to lifting, and offloaded lites can be deposited into racks or cases, or on to other transport conveyors in either vertical or horizontal planes.

Click on the new VIDEO LIBRARY button on the left of this page to watch the video ROBOT HANDLING EQUIPMENT and see ROBOLOAD-PRO™ in action…….

.

Other automated handling equipment includes:

- Rotary rack-change carousels

- Linear rack-change carousels

- 180 degree turnover conveyors

- 90 degree transfer tables

- 90 & 180 degree pivoting transfers

- Tilt conveyors

- Tilt / Pivot conveyors

- Vertical Paternoster storage units

- High Speed Shuttles