ASHTON INDUSTRIAL SEAMMAXX PRO ON-LINE EDGE DELETION

11 March 2015

. Fully automatic on-line edge deletion of soft coated glass, mounted within SEAMMAXX-PRO arrissing/seaming lines. . Simultaneous operation with the seaming process means there is no cycle time penalty. . Can effectively double your glass cutting line output by taking away the burden of deletion.

Read more...

ASHTON INDUSTRIAL SEAMMAXX PRO

. Very high performance arrissing/seaming line in U-configuration and including fully automatic batching of random mixed glass sizes for the tempering furnace. . Average cycle time of just 8 seconds per piece and absolutely no labour when the line is fed directly from Breakout.

Read more...

ASHTON INDUSTRIAL SHAPESEAM PRO

. Probably the World’s only truly, fully automatic arrissing/seaming robot for randomly missed glass sizes and shapes without any pre-programming, up to 4500 x 2500mm, and with a typical output of up to 150 lites per hour.

Read more...

ASHTON INDUSTRIAL STRAIGHT LINE PIVOTING TRANSFER & HIGH SPEED TILT

. This film demonstrates the SEAMMAXX-PRO high performance arrissing/seaming line, with a unique transfer station that pivots thru 90 degrees while the glass is also turning 90 degrees, so both seaming stations can be mounted in a straight line layout.

Read more...

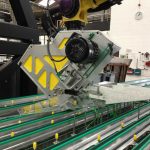

ROBOT HANDLING EQUIPMENT

. ROBOLOAD-PRO glass handling robots for loading and unloading single and multiple glass panes from and to vertical and horizontal planes. . 15 second cycle time on glass sizes up to 3 x 2m.

Read more...