STATE OF THE ART SEAMING UPGRADE FOR UPG

.

.

.

.

Mike and Joyce Cully (pic) are the owners of United Plate Glass, one of the premier independent glass fabricators and distributors on the US East Coast, and a long term loyal and valued customer of Ashton Industrial.

.

Mike joined his father and brother at United Plate Glass in 1983, eventually taking over as President in 2003 and Joyce has partnered in this journey with her husband Mike for over 40 years. UPG has grown from its original 6 employees and 1 location to employing over 235 people at its 3 locations in Pennsylvania, North Carolina and Maryland.

.

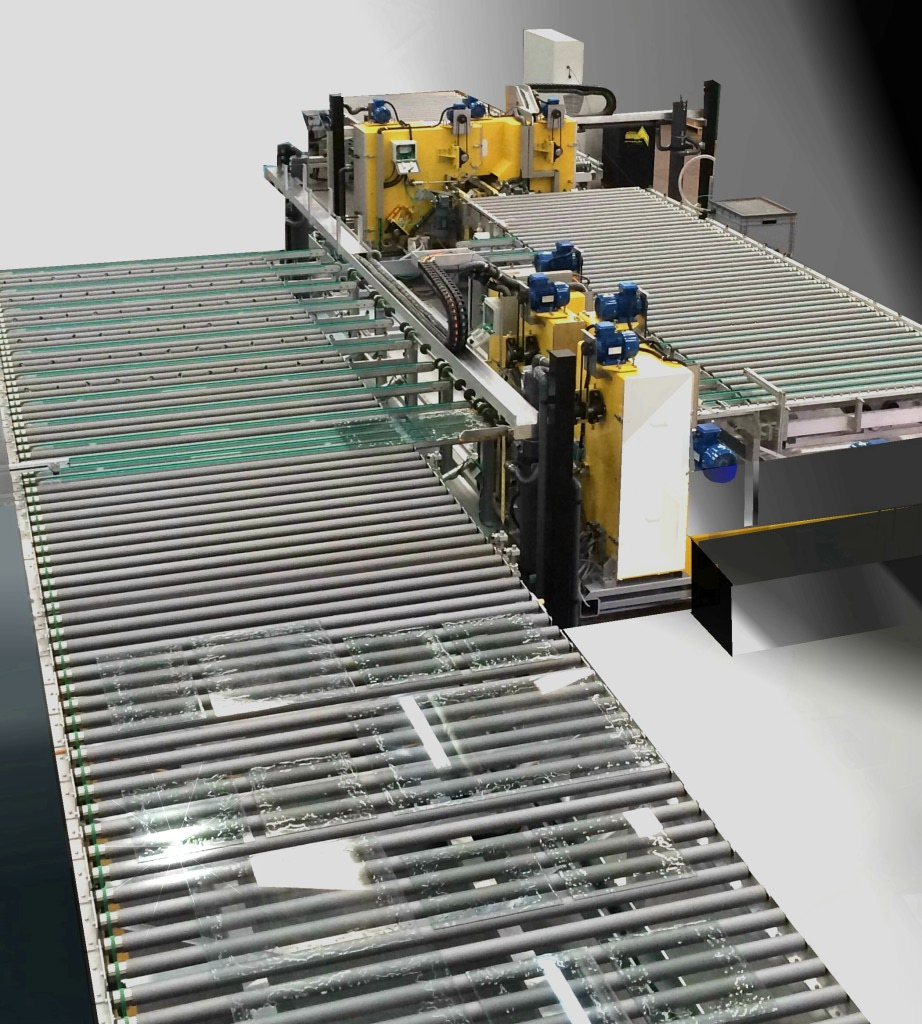

Multiple heavy duty Ashton UNIX™ air floatation seamers have been acquired over the past 10 years, like the installation of two in line machines in this photograph.

.

.

Now we are delighted to confirm receipt of an order for a new SEAMMAXX-PRO™ fully automatic seaming, washing and furnace batching line signed with Ashton’s Business Development Manager, Richard Green, in a meeting with Mike and Joyce, and Director Cory Brown, at the 2022 GLASSBUILD show.

.

.

.

Cory explains:

.

“The process of tempering is an expensive endeavor. To increase the ROI you need to obtain a high bed utilization and also have the ability to continuously feed the furnace with product. Without doing both you will never realize the true potential your investment. As furnace bed sizes increase the ability to accomplish both of the aforementioned items becomes unattainable without either a tremendous amount of labor or introducing automation into the process.

.

We recognized we were not realizing the full potential of our investment and sought out a partner that could help us achieve the quality seamed edge we had been accustomed to with our Ashton UNIX manual seamers, but also introduce automation into the process to keep up with the demand of the tempering furnace.

.

.

.

We arrived at the Ashton SEAMMAXX-PRO to help us accomplish our goal.

.

.

.

A point I feel is commonly overlooked in the tempering process is the quality of the edgework. The quality of glass coming out of a furnace is only as good as the edgework it Is sent in with. If there are imperfections in the edgework quality the tempering operator will need to compensate for this resulting in unnecessary distortion and subpar quality product.

.

Ashton is able to produce a high quality seam while also being forgiving to minor imperfections that can occur in the breakout process.”

.

.

.

For full history, products and project picture gallery:

.

.

.

.

.

.

.

.

.

• 108 Grundman Drive, Butler, PA 16001 1-800-772-7783 Toll free 724-848-7400

• 1104 Lincoln County Parkway, Lincolnton, NC 28092 1-866-361-8992 Toll free 828-970-6100

• 1666 Bowmans Farm Road, Frederick, MD 21701 1-866-691-1866 Toll free 240-608-4650