Employment

.

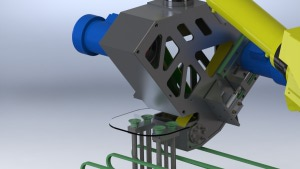

ASHTON INDUSTRIAL is a specialised manufacturer of automated glass processing machinery which is exported all over the world. Often customised to customers’ specific requirements, this equipment is in operation 24 hours a day and 7 days a week in many cases.

.

.

Full Time Skilled Production Fitters

Experienced in assembling and building large and sometimes complex equipment from drawings and pneumatic diagrams with minimal supervision.

Experienced in assembling and building large and sometimes complex equipment from drawings and pneumatic diagrams with minimal supervision..

General attributes: good spoken and written English language: physically fit: good workplace organisation ethic: flexible work style,

able to work overtime or on site as required; able to work effectively to deadlines, alone or as part of a team; able to provide own tools in line with job expectation.

.

Technical related experience: Ideally the applicant should be able to demonstrate the following or equivalent skill sets:

- 2 years’ experience in reading and working to engineering drawings with attention to accuracy and detail

- 5 years’ experience of typical mechanical skills including accurate marking out, drilling, tapping, cutting, use of power tools

- Experience of reading and working to detailed pneumatic diagrams

- 2 years’ experience of fitting motors, gearboxes, bearings, metal and plastic pipework, drive shafts and so on.

- Experience and appreciation of squaring and levelling machine frames, conveyors and other mechanical structures.

.

Qualifications: ideally the applicant will have a recognised time served apprenticeship and post-school vocational qualification in mechanical related topics such as C&G / BETEC etc.

Qualifications: ideally the applicant will have a recognised time served apprenticeship and post-school vocational qualification in mechanical related topics such as C&G / BETEC etc.

.

Remuneration according to skills and ability – applications to the Senior Manager of Operations, Stewart Barrass,

by phone 01279 624810

or email sbarrass@ashton-industrial.com

or by post to Ashton Industrial, South Rd., Harlow, Essex CM20 2AR

Full Time Skilled Technician

To work on control systems for industrial machinery and production lines – Experienced in working with PLC and HMI and associated programming software, for fault-finding and support,and first-time commissioning and testing [FAT] of industrial production machinery: ability to program is not essential but desirable, training will be provided.

.

General attributes: good spoken and written English language: good workplace organisation ethic: flexible work style, able to work overtime or on site as required; able to work effectively to deadlines, alone or as part of a team; Fault-finding and Problem-solving mentality.

General attributes: good spoken and written English language: good workplace organisation ethic: flexible work style, able to work overtime or on site as required; able to work effectively to deadlines, alone or as part of a team; Fault-finding and Problem-solving mentality.

.

Technical related experience: Ideally the applicant should be able to demonstrate the following or equivalent skill sets in addition to the above:

- Experience of PLC remote access, able to connect remotely to equipment all around the world for fault finding diagnosis, and eventual on-line fixes.

- Experience of Ethernet networks like LAN, WAN, VPN

- AutoCad Electrical, including creation or editing BOM’s and schematics

- Ability to accurately read and understand and work to electrical schematics

- Able to fault-find and solve electrical wiring problems

- Experience in Variable Speed Drives / Inverter systems, preferred B&R, Omron/Yaskawa

- Experience in FAT and SAT testing (Factory Acceptance and Site Acceptance)

- Experience of on-site installation and testing work, UK and overseas

Writing technical manuals or documents -PLC control system

Writing technical manuals or documents -PLC control system- Desirable attributes might also include demonstrable experience in a similar manufacturing sector, basic typical mechanical skills like marking out, drilling, tapping etc, and experience of panel building and equipment wiring.

.

Remuneration according to skills and ability – applications to the Senior Manager of Operations, Stewart Barrass,

by phone 01279 624810

or email sbarrass@ashton-industrial.com

or by post to Ashton Industrial, South Rd., Harlow, Essex CM20 2AR

.

.

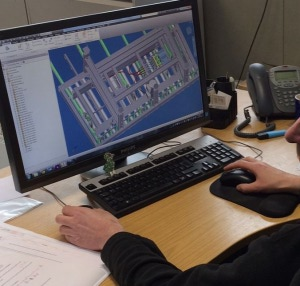

FULL TIME DESIGN ENGINEER

.

Role: mechanical design and detailing of machinery, parts and sub-assemblies.

.

Essential Skills:

Inventor, AutoCad Mechanical, MS Office

The applicant should be able to demonstrate experience working on special purpose machinery, fabrication, machining or similar skills.

Experience with sheet metal parts and laser cutting specs would be useful but not essential.

.

Responsibilities:

.

Design

Design

- Mechanical design of new products from concept sketches or design brief using Inventor 2015 and AutoCAD 2015 (both part of Autodesk Factory Design Suite 2015)

- Modification of existing products.

- Production of mechanical manufacturing and assembly drawings to the agreed ISO and quality standards.

- Research and specify suitable proprietary parts.

- Production of bill of materials (BOM).

- Maintain standard product library.

- Follow HSE machinery safety standards.

- Machinery Risk Assessment and EHSR for new and existing equipment.

- Oversee R&D projects during initial build up and test phase.

- Change control – follow company process for RFI and BOM updates.

- Production of machinery layouts for customer quotation purposes.

- Creation of customer laser logo’s.

- Liaise with the Control System Manager to specify and agree the suitability of motors, sensors etc.

.

Technical documentation

- Compile and maintain information for the machinery technical file.

- Production of machinery operation and maintenance manuals.

- Production of CE documentation including serial numbers, CE stickers and Declaration of Conformity.

- Photograph completed machinery for the user manual and future reference.

- Production of ‘best known method’ (BKM) documents to assist customers/production with part identification, maintenance or fitting.

- Production of machinery packing list.

.

MRP

MRP

- Completing new product request forms with the relevant technical information.

.

Customers

- Spare part quotations

- Telephone technical support.

- Customer returns technical support.

.

Suppliers

- Liaise with external suppliers on product selection, in terms of technical and commercial suitability.

.

Manufacturing

- Technical issue support

.

General

- Batch printing of mechanical and electrical drawings.

- Production of pdf documents for use by Purchasing.

- To support the engineering manager.

- To carry out other reasonable duties as may be required from time to time.

.

Remuneration according to skills and ability – applications to the Design Manager, Stephen Hutt,

by phone 01279 624810

or email shutt@ashton-industrial.com

or by post to Ashton Industrial, South Rd., Harlow, Essex CM20 2AR